Smoking chambers AIR are an universal compact device designed for the processing of food products, especially meat, fish, poultry and dairy products.

The Smoke chamber AIR in the technological process of food processing ensures drying, cooking and smoking, as well as controlled drying at low temperatures, cold smoke smoking and maturing with the possibility of automatic humidity control according to the technological process.

The technological process of heat treatment and cooling is controlled by a control system that ensures operation of the equipment. The control system enables arrangement of the technological process section of the heat treatment of the product according to the customer‘s requirements. Thanks to the control system, there is minimal loss of product weight.

Our Smoke chambers are supplied in standard execution with the frequency converter of the suction fans, which enables a flexible adjustment of the fan speed for individual sections of the technological process, which ensures maximum process efficiency!

There is a suction fan for each trolley to ensure perfect airflow and temperature distribution inside the chamber.

In comparison with the classic smoke chamber, AIR is equipped with a cooler, or so-called air osmosis – AIR, which provides air conditioning for controlled drying. This allows manufacturers, for example, to make cooked production during the week and semi-dry products during the weekend.

Smoke chamber AIR is supplied as standard with Cooling Showers: to cool down the finished product after heat treatment, the operation of this equipment is ensured by the control system based on the selected program section, either on time or at core temperature. After showering of the product the entire system is blown out automatically with compressed air.

The robust construction ensures perfect insulation and long service life.

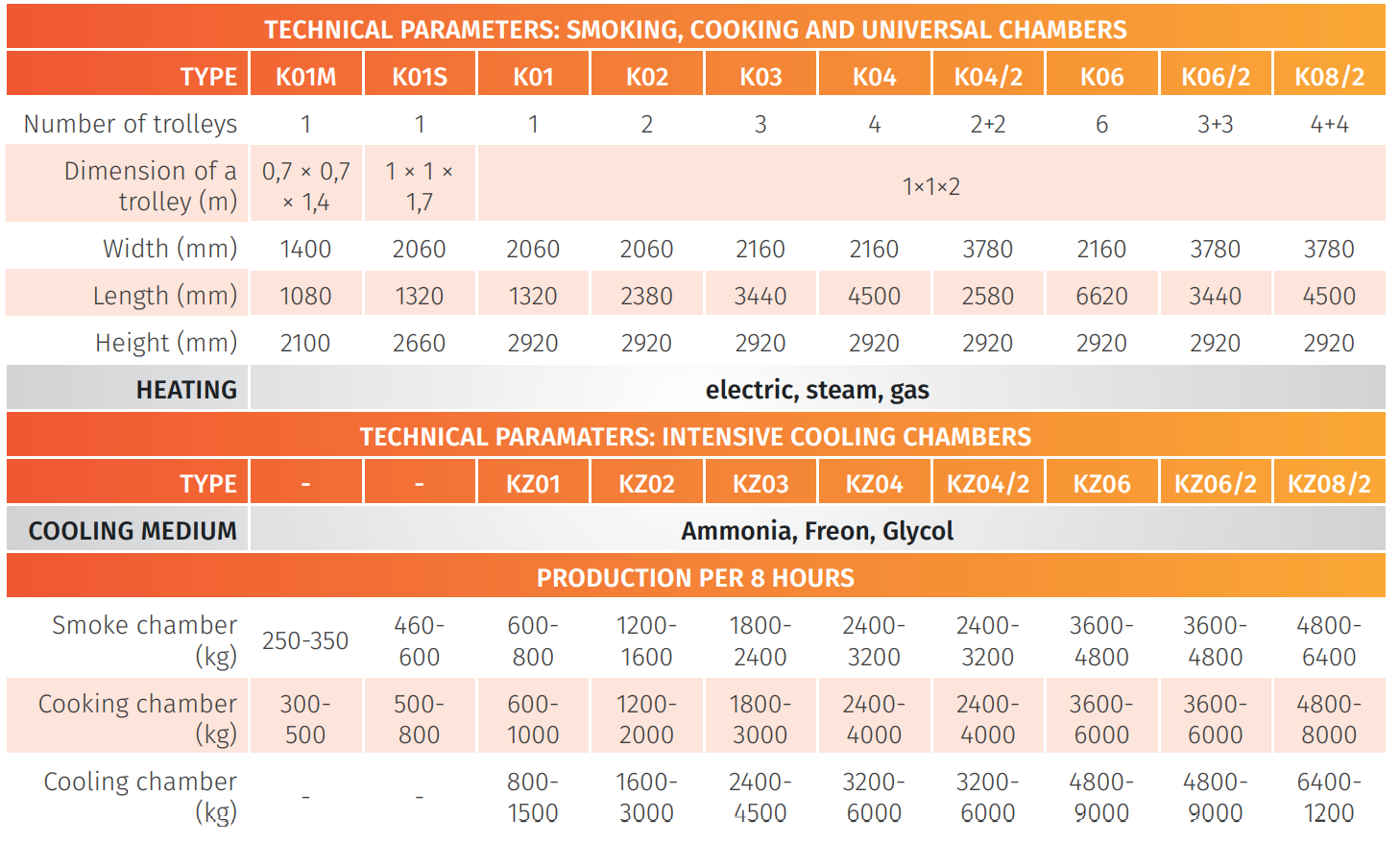

Heating of the chamber can be:

• Electric

• Gas

Are you interested in our devices?

Feel free to email us with your inquiry. We will be happy to deal with you.