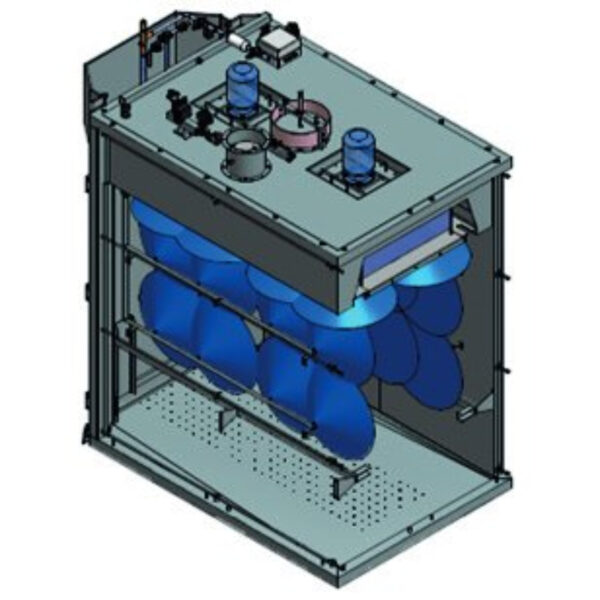

Device designed for automatic showering, intensive cooling and ventilating of smoked products after heat treatment without any further handling. Intensive cooling reduces weight losses comparing to conventional shower cooling. Ensures a rapid transition between critical temperature (formation of microorganisms), which extends product durability and allows immediate dispatch of products.

Cooling is processed in the following phases:

• Cooling with an intensive water shower with air flow blowing up at a core temperature of 30 – 35°C while the shower is controlled by intervals.

• Air flow cooling at 0 – 5°C. At this stage, the product is cooled to the desired temperature, which can be below + 8°C.

Technological cooling process is controled by control system that ensures operation of equipment. The control system enables arrangement of the technological process section and automatic operation of the product cooling process according to the customer’s requirements.

The robust construction ensures perfect insulation and long service life. The cooling source of the chamber can be (based on the customer requirements):

• R404A

• Ammonium

Are you interested in our devices?

Feel free to email us with your inquiry. We will be happy to deal with you.